The production of Liquefied Natural Gas (LNG) is an energy and cost-intensive process, necessitating a balance between operational efficiency and HSE considerations. The importance of optimising safety processes to address these challenges can not be overemphasised.

There is a need to ensure that the design and operational parameters of LNG liquefaction cycles consider operating costs, capital costs, environmental impact, personnel, and asset safety concerns.

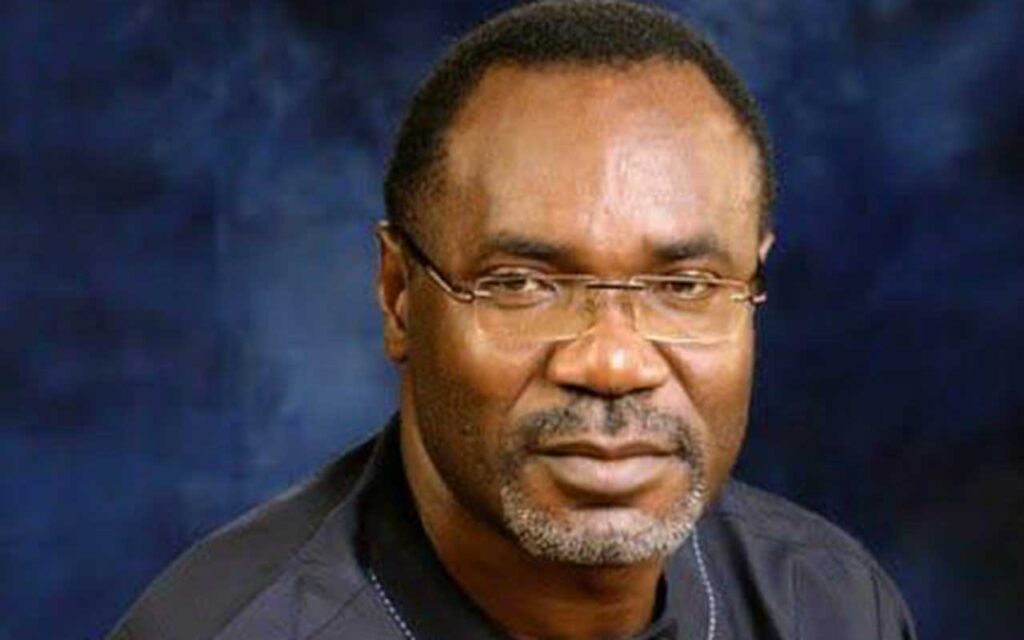

Liquefied Natural Gas Plants Operations and Competency Assurance Specialist, Dr. Tula Olawe, has identified some of the challenges in complying with stringent regulations in the production of LNG, and the complexities involved in balancing environmental compliance with operational profitability, and insists that prioritising safe practices is fundamental to maintaining continuity in the industry.

“The Liquefied Natural Gas (LNG) industry is characterised by its complex operations and potential hazards, which necessitates the need for robust risk management frameworks to ensure safety and efficiency. We must embrace a risk-based approach in the LNG industry, and advocate for the development of industry standards that not only identify risks at individual production sites but also establish comprehensive occupational health and safety management systems,” he stated.

Dr. Olawe believes that creating a holistic approach that reduces risks and addresses potential safety concerns in the industry is crucial to ensuring that LNG remains a viable and sustainable energy source. “The LNG industry must focus on the human element of safety. Training, awareness, and a robust safety culture are essential in mitigating risks associated with operations.

“The industry’s commitment to safety is not just about adhering to regulations but also about fostering a proactive approach to identifying and addressing potential hazards. The environmental sustainability of LNG as a transistion fuel in the energy mix journey is another critical area of interest.

“While LNG is cleaner than other fossil fuels, its supply chain, including extraction, liquefaction, transportation, and regasification, has associated greenhouse gas emissions,” he added.

He reemphasised the need to focus on human resources when implementing HSE practices by focusing on capacity building to enhance human barriers and continuous enlightenment on the ever-evolving safety demands of practising in the Industry.

Dr. Olawe affirms, “Our HSE management frameworks in the LNG Industry emphasized the need for regular audits, inspections, and maintenance to prevent accidents and ensure the safety of personnel, assets, and the environment. Training and competency development are integral components of these frameworks. Ensuring that personnel are well trained as critical human barriers and aware of the risks associated with LNG operations is critical for maintaining a high safety standard. This should include specialized training for handling emergency response procedures and understanding the operational characteristics of LNG facilities.”

Recognising the impact of upcoming technology like AI in improving the overall operational efficiency, and adherence to industry regulations, and safety he urged stakeholders to continue to move in this direction in order to keep industry practices at a standard that is safe for both employees, assets, and the surrounding environments.

“Technological advancements have also played a significant role in enhancing risk management in the industry. Innovations in monitoring and control systems, leak detection technologies, and advanced safety equipment have contributed to reducing risks and improving response capabilities in the event of an incident. We must continue implementing measures that minimise carbon footprints and emissions, enforcing the use of technologies for cleaner energy production.”